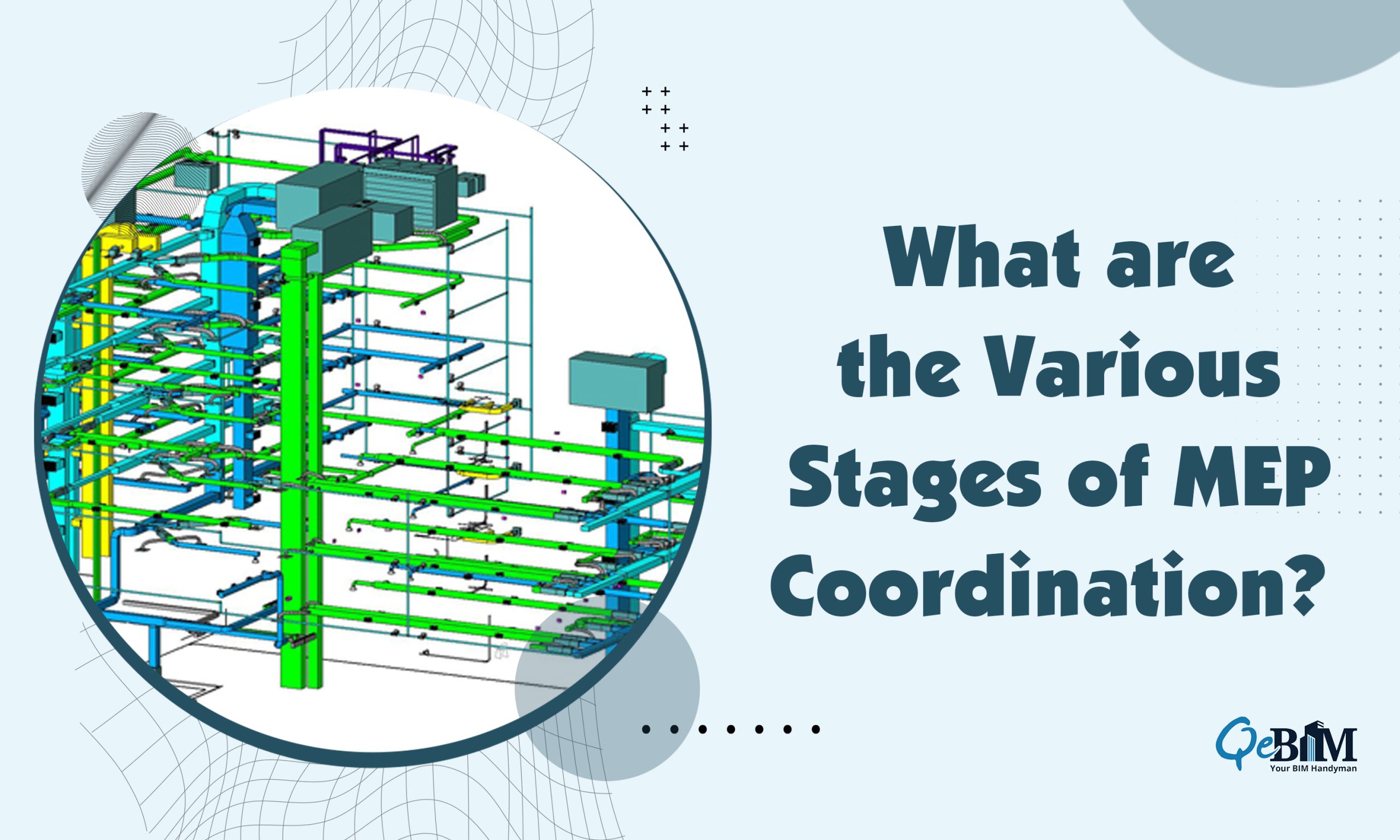

In the world of construction, the coordination of Mechanical, Electrical, and Plumbing (MEP) systems is crucial for the successful execution of any project. MEP coordination ensures that these essential systems work harmoniously within the built environment, maximizing efficiency and minimizing conflicts. However, achieving seamless coordination involves a series of meticulous stages that require attention to detail and collaboration among various stakeholders. Let’s delve into the typical stages of MEP coordination to understand the intricate process better.

7 Crucial Stages of MEP Coordination

Stage 1: Initial Assessments

The primary stage of MEP coordination begins with a thorough review of consultant’s single line drawings as well as structural plans for MEP Systems. This stage sets the foundation for the entire process, as it provides insights into the project scope, requirements, and constraints. Understanding the architectural and structural elements is crucial for integrating MEP systems hassle-free into the building design.

Stage 2: Crafting a Digital Blueprint

Once the initial review is complete, the next step is to create a 3D model of the MEP systems. Leveraging MEP BIM Services, designers develop a virtual illustration of the mechanical, electrical, as well as plumbing components within the building. This digital model serves as a collaborative platform for visualizing the systems’ layout and identifying potential clashes.

Stage 3: Clash Detection & Coordination

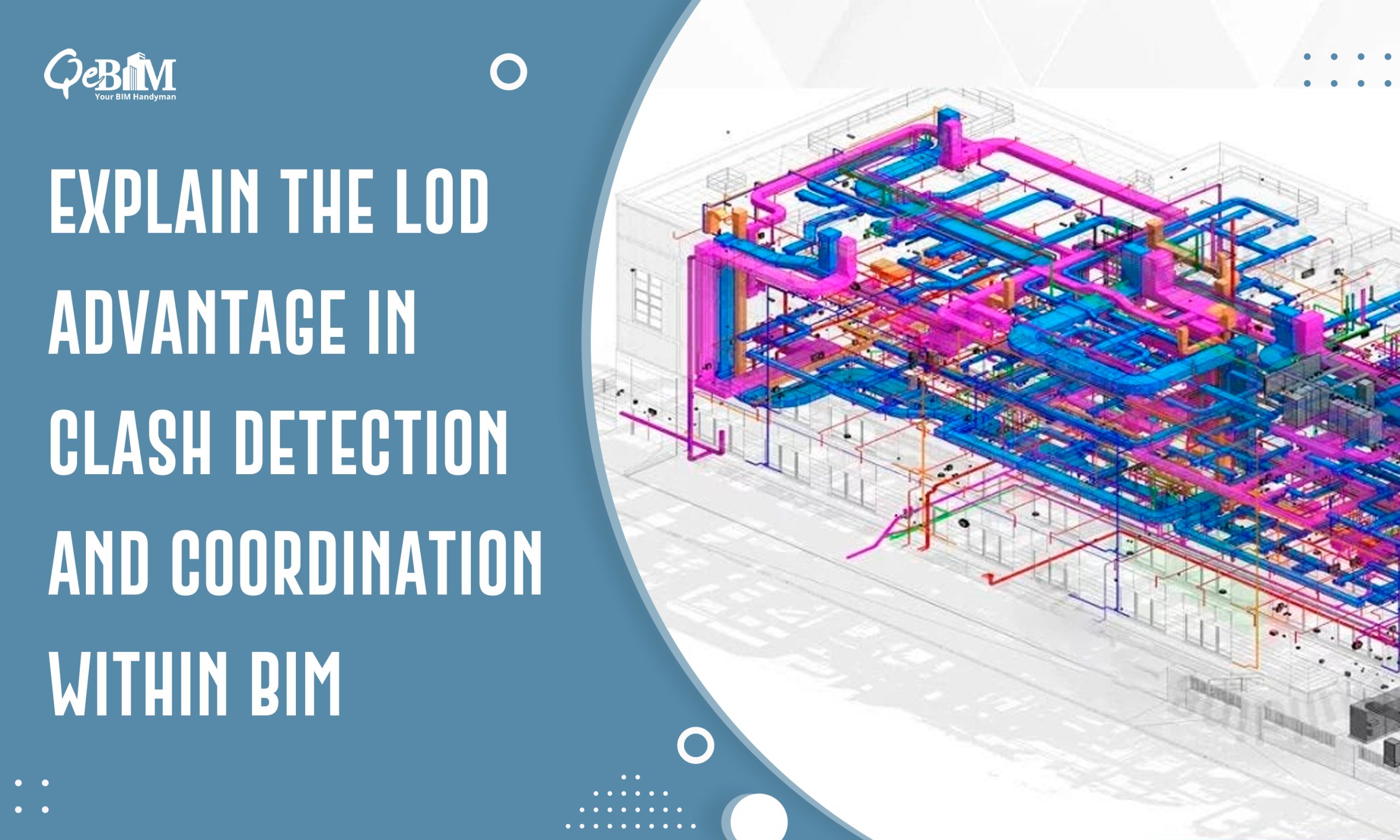

Clash detection is a pivotal stage in MEP coordination, where potential conflicts between different building systems are identified and addressed. Using specialized software and apt BIM Coordination Services, clashes such as ductwork intersecting with structural elements or piping conflicting with electrical conduits are detected early on. Resolving these clashes promptly minimizes rework and ensures smooth installation during the construction phase.

Stage 4: Coordinated Drawings and Documentation

With clashes resolved, the focus shifts to creating MEP coordinated drawings that reflect the finalized MEP system layout. These drawings provide detailed information with add on notes and comments for contractors and installers, guiding them in implementing the systems accurately. Clear communication and collaboration among the design team, contractors, and subcontractors are essential to produce comprehensive coordinated drawings.

Stage 5: Detailed Service Design

In this stage, detailed service drawings are generated to provide a deeper understanding of individual MEP components and their specifications. These drawings include information on equipment sizing, material specifications, installation details, and connections. Clear and precise service drawings facilitate smooth procurement and installation processes, minimizing errors and delays.

Stage 6: Precision Fabrication

Post service drawings, if needed, fabrication, spool, and hanger drawings are created as they are instrumental in the prefabrication and installation of MEP components. These drawings provide detailed instructions for fabricators to manufacture ductwork, piping, and other system elements off-site. Additionally, spool and hanger drawings help streamline the installation process by guiding installers on the precise positioning of MEP components within the building structure.

Stage7: As-Built Changes and Records

As the construction progresses, modifications to the MEP systems may be necessary to accommodate site conditions or design revisions. As-fitted changes involve updating the digital model and drawings to reflect these alterations accurately. This stage ensures that the final installed MEP systems align with the as-designed specifications, facilitating efficient operation and maintenance in the long run.

Conclusion:

MEP coordination encompasses a multifaceted process demanding careful planning, collaboration, and keen eye to detail. Adhering to the outlined stages empowers construction teams to adeptly navigate the intricacies of MEP coordination, guaranteeing the seamless integration of mechanical, electrical, and plumbing systems within the built environment.

Embracing advanced technology, fostering communication, and prioritizing coordination are the key to achieving seamless MEP integration and delivering high-quality construction projects.