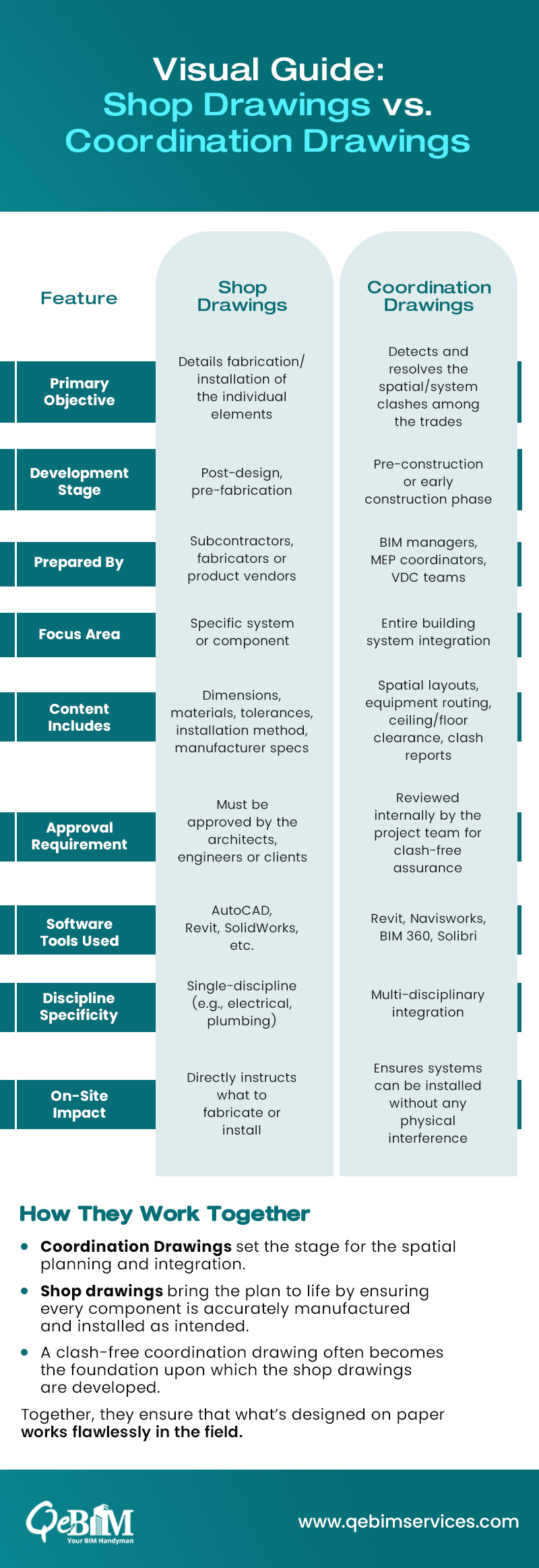

Introduction: Why the Distinction Matters

In large-scale and detail-intensive construction projects technical drawings stand out for their critical roles. Technical drawings comprises of many distinct types of drawings among which are Shop Drawings and Coordination Drawings. Although they may seem similar at first glance, they serve very different purposes. From fabricating a system to integrating it within the overall structure they do differ.

Understanding this distinction helps the project teams to avoid miscommunications, reduce errors and streamline the workflows especially when working with the Shop Drawing Services provided by the specialized outsourcing partners.

These drawings are the cornerstones of efficient project execution and are indispensable in BIM-enabled construction environments.

What are Shop Drawings?

Definition:

These are the detailed and precise drawings developed by the contractors or fabricators to illustrate how the individual components (like ductwork, steel structures or cabinetry) will be manufactured or installed.

Purpose:

To translate the design intent into fabrication-ready documentation, complete with the specifications, tolerances as well as the installation guidelines.

Key Features:

- Highly detailed, system/component-specific

- Reflects actual field conditions and installation methods

- Prepared after reviewing the architectural and engineering drawings

- Serves as a fabrication and installation guide

- Requires formal review and approvals

What are Coordination Drawings?

Definition:

These are the multidisciplinary composite drawings that helps to align the MEP systems with the structural and architectural elements hence ensuring that no spatial clashes are caused during the construction.

Purpose:

To facilitate the clash detection and resolution between the different building systems before installation, saving both the time and even the costs.

Key Features:

- Collaborative across multiple trades (HVAC, electrical, plumbing, etc.)

- Used in virtual design coordination (VDC)

- Developed using 3D modeling tools like Navisworks or Revit

- Aids in sequencing and installation logistics

- Helps to maintain the spatial clearances and serviceability

Conclusion: Clarity Drives Constructability

Considering the construction scenario where the timelines are tighter and the errors are quite costly, distinguishing between the Shop Drawings and Coordination Drawings is essential for the project success.

By approaching the experts offering the Shop Drawing Services, the AEC firms can ensure the precision in execution while maintaining the alignment with the broader coordination strategy.

The right drawings at the right time:

- Prevents the costly reworks

- Accelerates the fabrication and installations

- Ensures the compliance with the design and codes

- Enhances the collaboration across disciplines

Together, they bridge the gap between the concept and construction making coordination smarter and delivery smoother.